Florida’s 5-Star Rated Proslat Installation Experts — Garage, Commercial, and Industrial Storage Solutions

30% OFF GROUND FLOOR COATINGS

(Discount applies to regular retail price)

Hyper-Durable Concrete Coatings Ready!

SEE THE Gator Epoxy DIFFERENCE IN ACTION

Before

After

Unclutter Your Space

Make the most of your space with customizable storage solutions from Gator Epoxy.

Our Services

Understanding that your home is your greatest pride, we provide customized solutions that blend durability, style, and unmatched quality to make your family proud.

GET TO KNOW Gator Epoxy

From everyday wear to tough stains and cracks, damaged floors can affect your home.

UV Factory Direct Savings

5 Star Reviews

SEE THE Gator Epoxy DIFFERENCE IN ACTION

Before

After

GET TO KNOW Gator Epoxy

From everyday wear to tough stains and cracks, damaged floors can affect your home.

With Gator Epoxy, you're protected by premium coatings that come with a life of home warranty against delamination.

Factory-Direct Pricing

High Quality Quality

33 Colors to choose from

Upgrade Your Floors With Unmatched Performance

From everyday wear to tough stains and cracks, damaged floors can affect your home.

UV And Chemical Resistant

Quick Cure Rate

Non-Toxic

Unmatched Resistance

Gator Epoxy - AS EASY AS 1, 2, 3

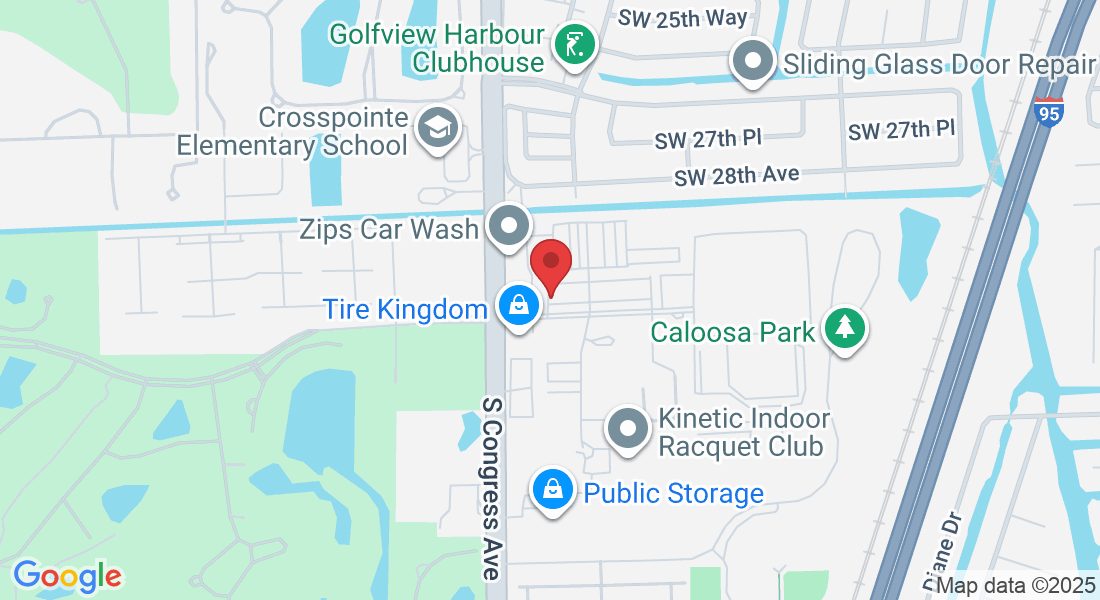

Hundreds Of Successful Installations Across Florida

Engineered for garages, patios, pool decks, driveways, and sidewalks, Gator Epoxy are guaranteed to enhance both beauty and performance in every space.

Transform your areas into low-maintenance, high-performance environments!

Testimonials

See What Our Customers Have To Say

5.0

Ratings

5.0

Ratings

5.0

Ratings

5.0

RATINGS

5.0

RATINGS

5.0

RATINGS